Nordic Welding Expo 2024

Nordic Welding Expo 2022

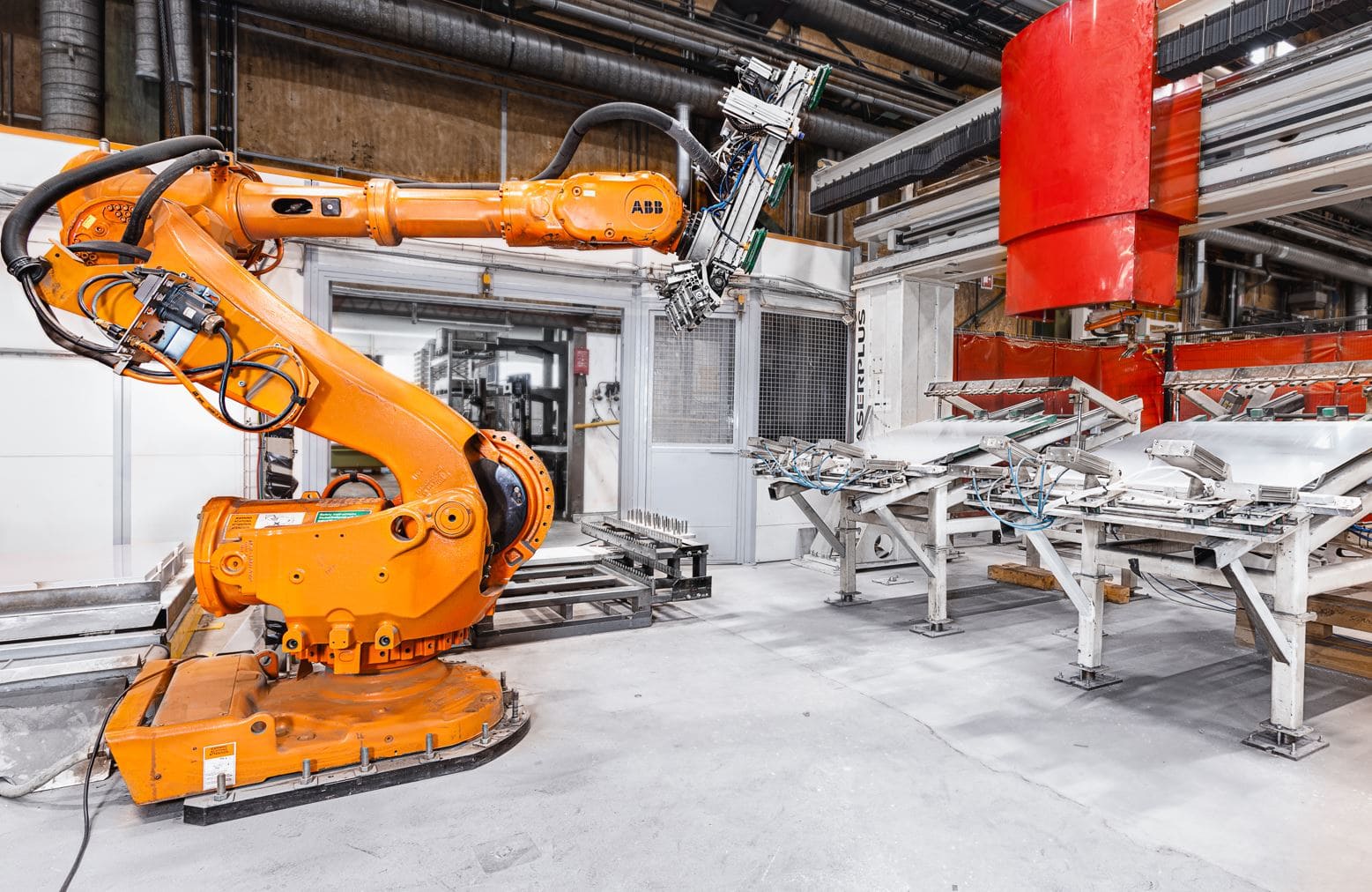

Ionix is modernizing Turula Engineering Oy’s production machines

The close cooperation between Ionix and Fastems is bearing fruit

Ionix 10 years

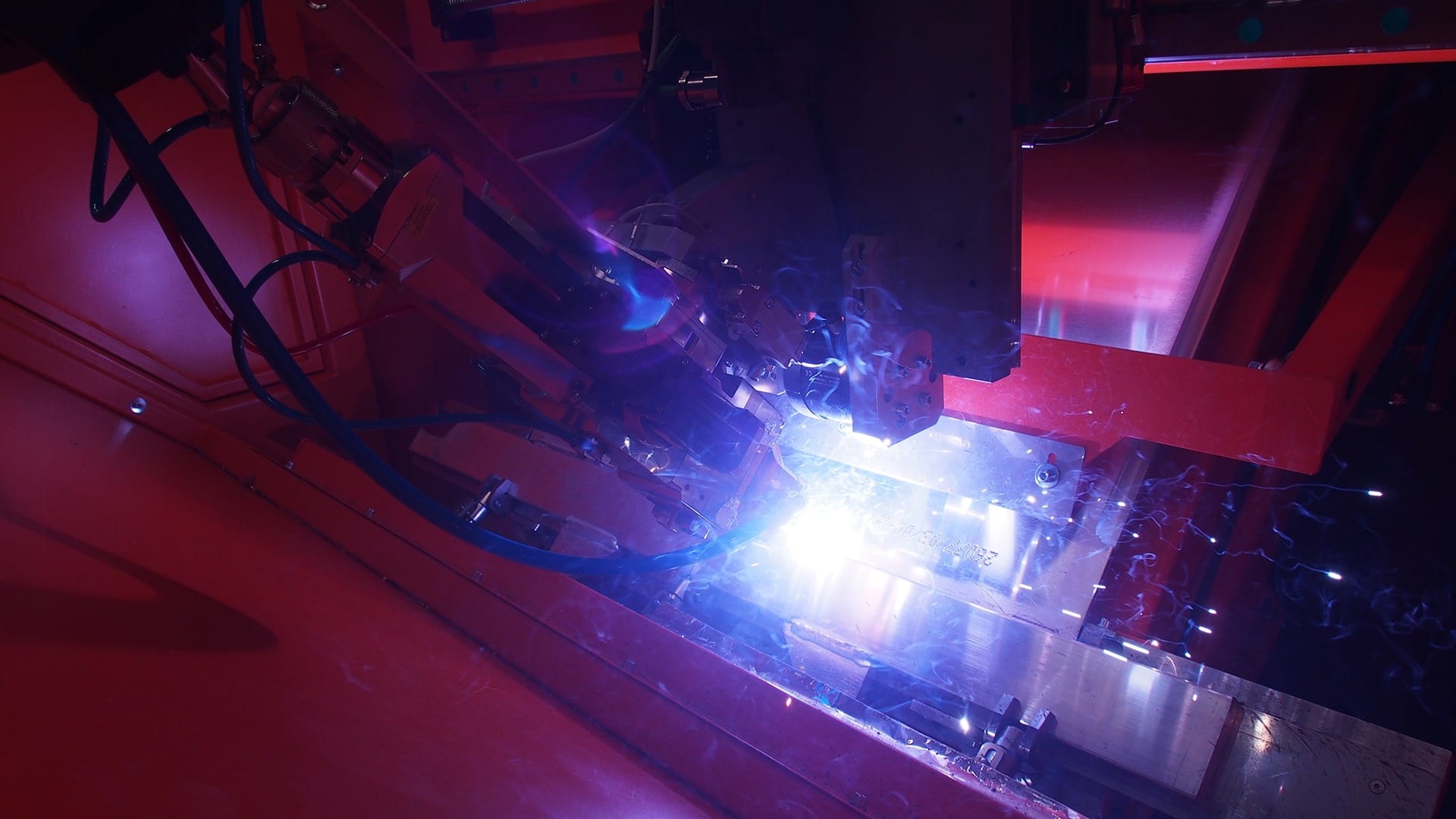

Vahterus achieved high-level goals in cooperation with Ionix

Teknologia 22 exhibition on May 3-5, 2022

New web pages are here!

![reliable-partner-logo[1]](https://www.ionix.fi/wp-content/uploads/2023/03/reliable-partner-logo1-300x118.png)